UNITYWATER CEO ANNA JACKSON ON CREATING A SUSTAINABLE UTILITY

HORIZON POWER UNLOCKS CLEAN ENERGY POTENTIAL WITH DERMS

WEARABLE TECH AT THE FOREFRONT OF WORKER SAFETY

WATER SEWER ELECTRICITY GAS www.utilitymagazine.com.au Issue #36, November 2022

Easy transportation Simple implementation Operator and equipment safety 1300 FMT FMT (368 368) Melbourne 1/53-57 Rimfire Drive Hallam VIC 3803 Brisbane 2/5 Percy Drive Brendale QLD 4500 Perth 3/48 Hardey Road Belmont WA 6104 The water supply operator’s kit H2O WATER KIT

As you can see from this issue’s cover image, I interviewed Unitywater’s new CEO, Anna Jackson, on current challenges and innovations in the water sector, and her vision for the utility. While our chat covered a few different topics, there was one clear underlying theme to everything we talked about, and that was sustainability.

Whether we were discussing recent projects, digital transformation, or the next generation of utility workers, the clear message was that everything needs to be embedded with a sustainable lens if we’re going to be successful in meeting future demand. It was a great conversation, which you can find on page 24.

This theme is even more present in the energy sector as it continues to undergo its own transition to renewable energy. We have a lengthy feature on renewables, looking at everything from the impact of Horizon Power’s Distributed Energy Resources Management System (DERMS), to construction of the country’s largest approved grid-forming battery, and specifics on what future solar technologies will look like.

The impact of not focusing on climate change can also be seen in our disaster management feature where Tweed Council have outlined their ongoing flood response and recovery and the resilience measures in place to help prepare for future events.

Safety is also a critical topic across the utility sector and there are constantly new innovations and technologies that are helping keep our networks and workers safe. On the employee side of things, SA Water is trialling smart wearable devices to explore how technology can lead to greater health and wellbeing outcomes. While Endeavour Energy is focusing on training energy workers to meet new skills requirements in a changing electricity supply industry.

This edition of the magazine – the last for 2022 – also explores the important topics of pipeline integrity and leak detection and what water utilities can do when it comes to proactive management and maintenance; the latest in Horizontal Directional Drilling (HDD) and corrosion; as well as the role home energy management plays in energy efficiency and keeping bills low for customers.

As we near the end of the year, this is often a time for utilities and organisations to reflect and put in place plans for 2023. Utility Magazine has had a great year with in-person events returning, and our own virtual Digital Utilities Conference being held in June, as well as the fantastic support we continue to receive from utilities all around Australia. So thank you for your involvement and interest in the magazine, and we can’t wait to grow even more next year.

Jessica Dickers Editor

Managing Editor Jessica Dickers Assistant Editor Mikayla Bridge Journalists Lauren DeLorenzo Stephanie Nestor Holly Tancredi

Todesco

Thompson Design Manager Alejandro Molano Designers Ozlem Munur

Martin

Harris National Media and Events Executives Rima Munafo

Thompson

Circosta Marketing Manager Radhika Sud Marketing Associate Andie James Digital Marketing Assistants James Holgate Jackson Barnes Natalie Ta Publisher Chris Bland GM Growth and Strategy Laura Harvey Published by Cover image highlights our interview with Unitywater's new CEO Anna Jackson WATER SEWER ELECTRICITY GAS www.utilitymagazine.com.au UTILITY MAGAZINE NOVEMBER 2022 UNITYWATER CEO ANNA JACKSON ON CREATING A SUSTAINABLE UTILITY WEARABLE TECH AT THE FOREFRONT OF WORKER SAFETY HORIZON POWER UNLOCKS CLEAN ENERGY POTENTIAL WITH DERMS

Media Enterprises

The Commons

Gipps St, Collingwood VIC 3066

welcome November 2022 ISSUE 36 1 Drop me a line at jessica.dickers@monkeymedia.net.au or feel free to

me on

to let me know what you think. Don't forget to follow Utility Magazine on social media – find us on LinkedIn, Twitter and YouTube.

Rebecca

John

Luke

Danielle

Brett

Christine

Monkey

ABN: 36 426 734 954 C/-

36–38

P: (03) 9988 4950 monkeymedia.com.au info@monkeymedia.com.au utilitymagazine.com.au info@utilitymagazine.com.au ISSN: 2203-2797

call

03 9988 4950

FROM THE EDITOR

THIS DOCUMENT HAS BEEN PRODUCED TO INTERNATIONAL ENVIRONMENTAL MANAGEMENT STANDARD ISO14001 BY A CERTIFIED GREEN PRINTING COMPANY.

INDUSTRY INSIGHTS

In July this year, Anna Jackson joined South East Queensland water utility Unitywater as its new CEO. Previously SA Water’s General Manager Strategy, Engagement and Innovation, Ms Jackson is keenly aware of the challenges facing water utilities and recent developments in customer engagement. She sat down with Utility Magazine Editor Jessica Dickers to discuss the impacts of climate change and population

RENEWABLES

living in regional and remote Western Australia will soon be able to embrace clean energy technologies and reduce their energy bills, with Horizon Power rolling out industry leading technology

create smart, integrated, and cleaner energy systems across the state from early 2023.

In a recent announcement by Federal Energy Minister, Chris Bowen, ARENA will fund an extension of the Australian Centre for Advanced Photovoltaics (ACAP).

Final negotiations are in process on the research program and partnerships, with work expected to start in 2023. Here, ACAP outlines breakthroughs in solar technologies, what the next generation of photovoltaic technologies looks like, and the role this plays in grid overhaul.

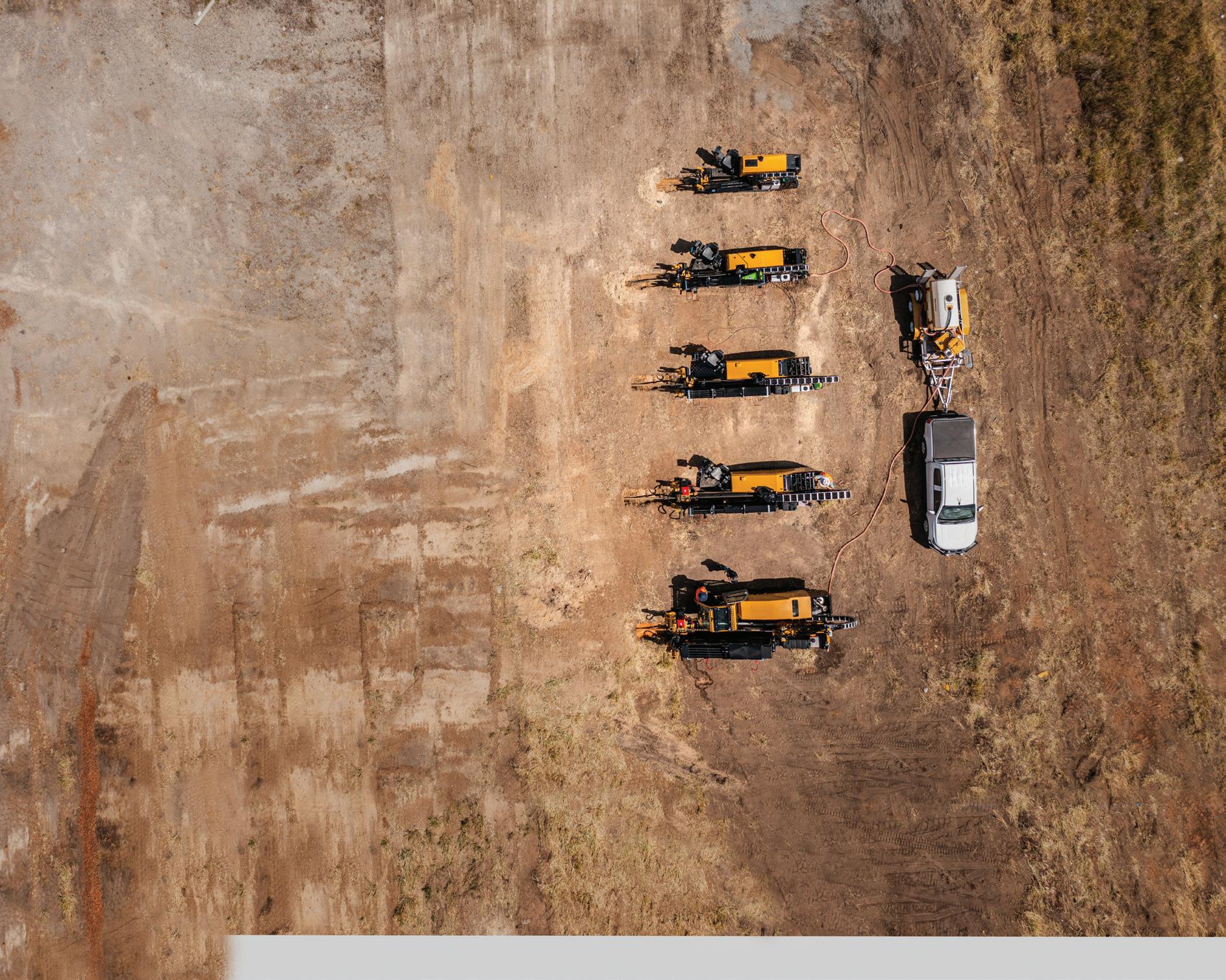

What are some of the new innovations increasing capabilities in the microtunnelling industry?

As new technologies and innovations emerge in the microtunnelling industry, contractors’ capabilities to meet some of the industry’s toughest challenges continue to grow. For example, very hard rock used to result in most contractors turning down projects or stopping a job part way through when they unexpectedly hit these conditions. This is because most microtunnelling tools struggle to drill through very hard rock and install a pipeline to specifications, but new cutting-edge trenchless equipment can now do so with high precision. This is only one example, there are a number of new technologies that are helping to pave the way for the future of microtunnelling.

2

RETAIL, BILLING & CRM Beating the energy crisis with home energy management 84 CORROSION Seeing through hidden corrosion in utilities 86 78 84 24 32 90 UTILITY • NOVEMBER 2 022 WWW.UTILITYMAGAZINE.COM.AU

CONTENTS

The next generation of solar technologies 44

Connecting renewable assets to the transmission grid 48 The largest approved grid-forming battery in Australia 50

Unitywater CEO Anna Jackson on creating a sustainable utility 24

growth, the uptake of digital meters, and the vision for her new role – all of which tie in with an overarching theme of a sustainable water future. Making waves: transforming the water industry 28 Genuine water collaboration through Reconciliation Action Plans 30

& SUBSTATIONS The building blocks of the MacIntyre Wind Farm 78 Working together from concept to completion 80 HORIZONTAL DIRECTIONAL DRILLING (HDD) New Horizontal Directional Drill ticking every box in Healesville 82

TRANSFORMERS

Industry leading tech unlocking clean energy potential 32

The future of energy depends on DERMS 36 Delivering geospatial intelligence for Horizon Power ....................... 38 Urgent action is needed to accelerate Australia’s energy transition......................... 40 Australia’s energy future is renewable and it’s here. Are you ready? 42

People

to

November 2022 ISSUE 36 3 In each issue Welcome from the Editor ������������������������������������������������������������������������������������������������������������� 1 A word from Energy Networks Australia ���������������������������������������������������������������������������������� 4 A word from WSAA ����������������������������������������������������������������������������������������������������������������������� 6 News briefs ������������������������������������������������������������������������������������������������������������������������������������ 8 Advertisers’ index ���������������������������������������������������������������������������������������������������������������������� 92 Editorial schedule ���������������������������������������������������������������������������������������������������������������������� 92 54 70 UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 60

Tweed's response to flood showcases resilience ....................54 The Tweed Shire’s flood recovery continues to gather momentum as the full extent of the record flood of February-March 2022 becomes clearer. How safety is becoming one of the most critical smart city applications 58 To help identify and act on current and potential future public safety threats, smart city technology is a critical resource for leaders of city councils.

DISASTER MANAGEMENT

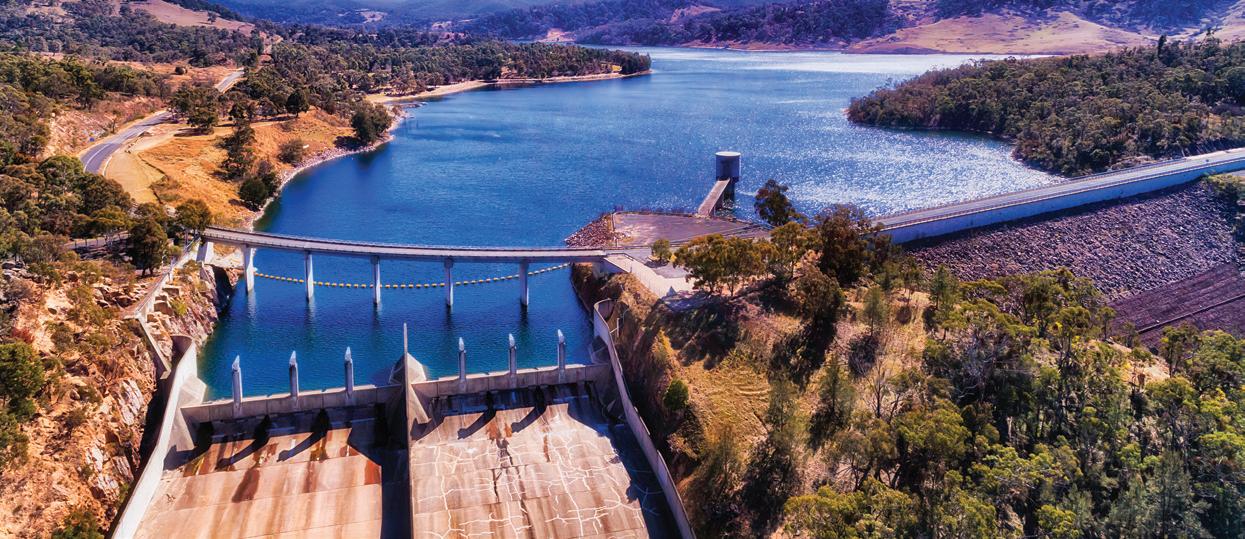

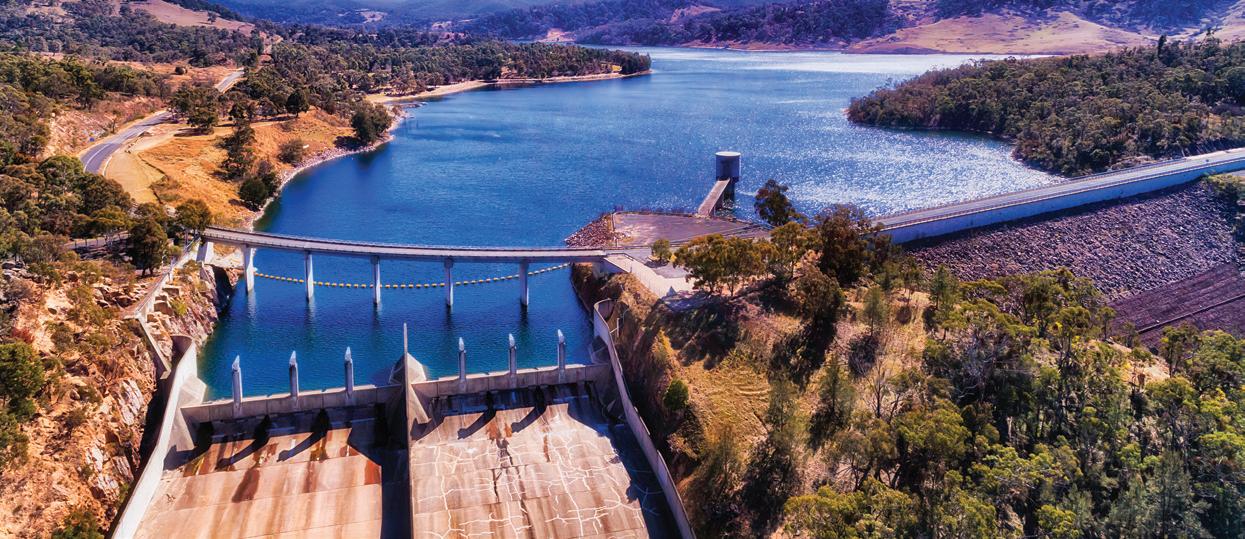

LEAK DETECTION Restoring Goulburn-Murray’s pipeline for water efficiency 70 In March 2021, Goulburn-Murray Water (GMW) began delivering the Water Efficiency Project across the GoulburnMurray Irrigation District. All construction works required as part of the $177.5 million project will be completed by the end of 2023 and are funded by the Federal Government to support the recovery of environmental water in the MurrayDarling Basin. Holistic water management: navigating the infrastructure cliff ....................... 74 An innovation leap for network leak detection 76

SA Water team wears safety innovation ......................... 60 An innovative safety initiative is breaking new

a

to

technology can

to

and wellbeing outcomes. Maximise safety with integrated motorised racking devices 64 Building essential skills for modern grid transformation 66 Helping water companies prevent wastewater spills ........... 68

PIPELINE INTEGRITY &

SAFETY

ground in the Australian water industry, with 15 of SA Water’s fieldbased staff donning

range of smart wearable devices

explore how new

lead

greater health

TRANSMISSION FRAMEWORK – MORE STRANDS THAN A BOWL OF SPAGHETTI

by Verity Watson, Head of Transmission, Energy Networks Australia

Transmission is a critical enabler to reach net zero by 2050, with a work program to deliver it way beyond that of recent decades. There is certainly plenty of noise about transmission with most states running to take on planning responsibilities for its delivery, but will the constant change in the transmission framework, national and state, help or hinder the delivery of the right projects?

There is recognition across the energy industry that transmission investment is critical to support the energy system transition at lowest cost to consumers, but it is difficult to keep track of the proliferating regulatory and investment processes projects must follow.

RELEVANCE OF THE NER FRAMEWORK

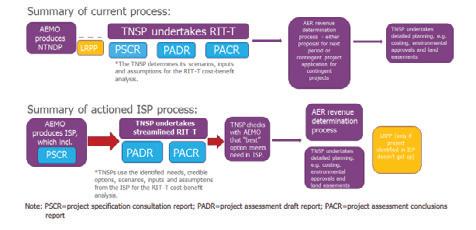

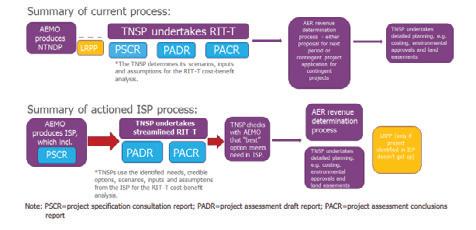

In the final report reviewing coordination of generation and transmission development in 2018, the Australian Energy Market Commission (AEMC) proposed a more streamlined planning and investment framework. Under the leadership of the Energy Security Board (ESB), with Energy Ministers and all three market bodies on board, a national actionable Integrated System Plan (ISP) framework was created in the national rules and commenced on 1 July 2020.

Later in 2020, the Australian Energy Regulator (AER) finalised the guidelines, and in 2021 issued a guidance note to articulate expectations for procurement strategy and engagement between the Regulatory Investment Test for Transmission (RIT-T) and Contingent Project Application (CPA) stage.

The proposed framework at the time had overwhelming support for the checks and balances it contained. This included appropriate segregation of duties between the planning and investment decision making. The 2022 ISP is the first ISP to be completed under the new framework.

Some projects recognised in the 2018 and 2020 ISPs are already completed (e.g. synchronous condensers and minor interconnector upgrades) while the major greenfield projects are well underway in the case of Project Energy Connect. Current target dates for these projects and other Renewable Energy Zones are around the second half of this decade. The aging synchronous generation fleet is not getting any younger and new transmission and generation are needed urgently. This is a significant infrastructure delivery program, the scale of which we haven’t seen before.

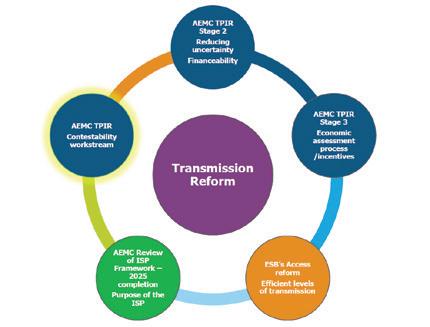

TRANSMISSION PLANNING UNDER CONSTANT REVIEW

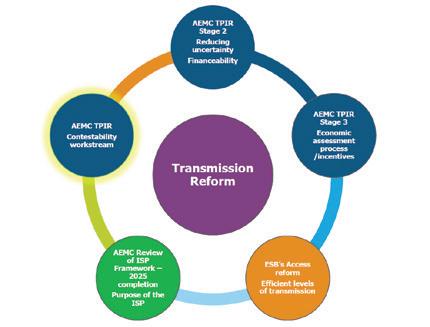

The original actionable ISP rules have had a few fix-up rule changes. Despite this, the AEMC has a number of stages in its current transmission planning review – incremental changes (Stage 2) and longer-term improvements (Stage 3) and whether there may be benefits in considering other models for planning and investment e.g. earlier contestability, see Fig 2. These review stages are in addition to the ESB’s transmission access reform and the review of the actionable ISP rules framework due to be completed by mid 2025. That’s some seven to eight reviews or rule changes in the space of five years. This creates a great deal of uncertainty for what is long lived infrastructure and its cost will be reflected in consumers’ electricity bills for decades.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 4 A

WORD FROM ENERGY NETWORKS AUSTRALIA

FIG 1 – COMPARISON OF THE PRE-ISP TRANSMISSION PLANNING FRAMEWORK AND THE PROPOSED ACTIONABLE ISP FRAMEWORK. SOURCE: AEMC, FINAL REPORT COGATI, 21 DEC 2018.

FIG 2 – TRANSMISSION REVIEWS TO SUPPORT THE EFFICIENT USE OF TRANSMISSION INFRASTRUCTURE AND TIMELY AND EFFICIENT INVESTMENT. SOURCE: AEMC.

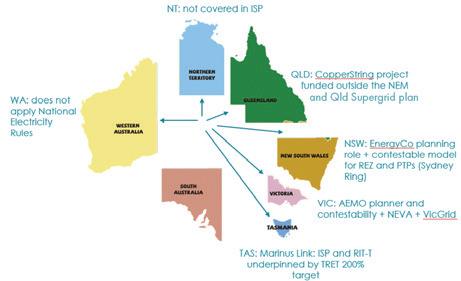

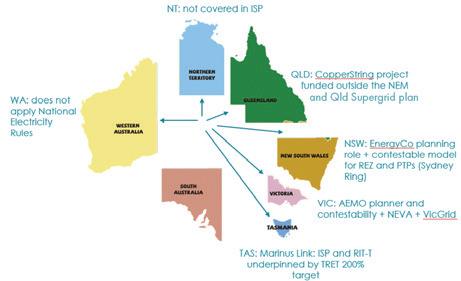

Regulatory processes that afford consumer protections are seen as too slow, the investment settings may be seen as not able to support the levels of investment involved and retirement of needed synchronous generation is moving more rapidly. To tackle this, some state governments have sought to bypass the rules and take matters into their own hands, a high-level view is shown in Fig 3.

HOUSTON KEMP.

HOUSTON KEMP.

Improving state planning and environmental approvals and costs would be helpful. Creating a spaghetti bolognese of models and processes is not.

VicGrid and the Consumer Trustee (Victoria and NSW) are both developing state-based plans for state agendas in a power system that is interconnected. There are now bits of national and state processes with varying connection standards and processes that need to be navigated. Queensland have recently announced their Energy and Jobs Plan to reach 70 per cent renewable energy by 2032.

The transition is gaining pace and the complexity of operating a stable and secure power system is challenging without adding additional coordination and complexity.

The NSW model for the delivery of Renewable Energy Zones (REZs) remains under development two years after the model was first mooted and is yet to be tested in practice. This is time we just don’t have to deliver

commissioned generation and transmission infrastructure if reliability is to be maintained. Victoria is considering its framework but is still at a high level and there is a time imperative with the looming generation retirements.

Bypassing the transparency and robustness of the national planning and investment framework, enabling the planner to implement its own plan with consumers paying, is like a move back to the quasi-state electricity commission approach – but does it resolve the issues of the significant construction work program required?

The external factors currently impacting the cost and timeliness of major transmission projects, such as cost escalation, supply chain and labour bottlenecks, environmental approvals and landholder concerns around development, and challenges of establishing social licence – won’t be addressed by contestability or by changing the party responsible.

Increasing the complexity of navigating the state and national processes and the parties involved in delivering and commissioning infrastructure at a time when timeliness is key may not reduce total system costs to consumers. These splintered frameworks are looking like they will stay. It is not just the state-based planning bodies – there are a range of additional activities and ongoing coordination costs for existing networks and the market bodies.

AEMO’s 2022 Electricity Statement of Opportunities (ESOO) highlights the importance of VNI (minor), QNI (minor) and PEC to meet reliability in the near term. With the expected closure of Yallourn and Vales Point power station towards the end of the decade, there is a reliance on the anticipated transmission, generation and storage projects in the pipeline being delivered on time.

Timely transmission development is needed to improve the reliability forecast later this decade. Rather than further fragmentation of the framework, adding coordination complexity and risks, it is time to work together to improve the resilience of the NEM as the economy seeks to electrify. Supporting the current pipeline of projects to commissioning and keeping the pipeline of projects manageable is what is needed to ensure the smooth transition to net zero.

UTILITY • NOVEMBER 2 022 WWW.UTILITYMAGAZINE.COM.AU 5

FIG 3 – STATE GOVERNMENTS ARE PURSUING THEIR OWN APPROACHES, CAN THE NER REGAIN RELEVANCE?

SOURCE:

A WORD FROM WSAA

IMPROVING WATER SERVICES TO REMOTE FIRST NATIONS COMMUNITIES

Many stakeholders across Australia are leading important initiatives in ‘Closing the Gap’ for First Nations peoples, addressing health, social, economic and other aspects. Yet amid this work, stories regularly emerge about remote communities with limited and sometimes no access to safe drinking water, poor health outcomes associated with a lack of clean and reliable water supplies, and unclear accountabilities for providing water services.

In August 2022 we were pleased to release a Preliminary Report into improving water services to remote First Nations communities. The report was commissioned in 2021 to:

• Review remote water services in Australia

• Elevate these issues in the national conversation

• Recommend ways to close the gap in the delivery of safe drinking water including water quality and water security

Water is core to life for First Nations people and has an important role in their connection to country. Protecting and managing water is seen as a custodial and intergenerational responsibility. The delivery of safe drinking water plays a critical role in the viability, self-determination, and sustainability of First Nations remote communities.

We know that for remote First Nations communities the delivery of safe drinking water is fundamental to closing the gap targets, particularly:

• Impact on public health

• Impact on remote living and integration with public housing

• Impact on wellbeing of people and communities

The Preliminary Report documents the arrangements for water servicing of remote communities across Australia. It outlines some preliminary findings and recommendations about how improving water can help close the gap – and where we can start.

In line with other studies, the Preliminary Report calls for a national drinking water database and national monitoring program for remote First Nations communities.

There is a need for a baseline study to document the delivery of safe drinking water to remote communities and, in particular, remote First Nations communities.

The full report is being finalised and we continue to work with governments and the urban water industry on how to progress these initiatives and embed them in a new National Water Initiative.

To view the Preliminary Report and the full report once it is released (expected in November 2022), please visit www.wsaa.asn.au.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 6

The

is flexible, scalable, and customisable – make life easier for you

your customers.

aptumo.com hello@aptumo.com Aptumo

and

by Echo Managed Services, the UK utility billing specialist.

next generation billing solution that puts you in control Powered

METER SEALS IN HIGH DEMAND

Being intuitively designed, robust, and secure enough to continue passing SCEC approval tests, it is time to put the spotlight on a classic meter seal that has truly stood the test of time.

From the meter seals range, the Tool Less Roto Seal continues to be Harcor’s most popular seal. Its ease of use and ability to be applied without special tools has resulted in high demand in both the commercial and government sectors.

Harcor has kept up the seal’s SCEC approval and resubmitted it for an up-to-date approval that was granted to ensure that use is not disrupted.

For those new to using the Tool Less Roto Seal, you essentially start by feeding the sealing wire through the

seal's orifices. Then you pull the free wire ends until there is the desired gap between the seal's body and what is being sealed. The tab on top of the seal is then twisted clockwise to secure the wire in place. Once secure, the tab is to be removed by bending it in either direction.

Harcor is a major supplier to the various energy providers based throughout Australia. Its range of meter security seals cover a diverse area within the utility industry supporting gas, water and electricity suppliers and contractors.

If you have any questions regarding the Tool Less Roto Seal, please visit harcor.com.au/collections/meter-seals-wire-presses or email sales@harcor.com.au.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 8 No. 407319937 Key management Meter security seals Contact us for more information about our comprehensive range of key cabinets. Trackable Serial Numbering Expose Unauthorised Access

NEWS | Sponsored editorial

1300 062 064 | polymaster.com.au 25 YEAR DESIGN LIFE

our range

See

QLD’S NEW TEN-YEAR ENERGY PLAN

Anew $62 billion clean energy future has been announced for Queensland – including the largest pumped hydro scheme in the world, which will supply clean, reliable and affordable renewable energy for half of Queensland’s entire energy needs.

The Queensland Energy and Jobs Plan includes:

• 70 per cent of Queensland’s energy supply from renewables by 2032 (80 per cent by 2035)

• Two new pumped hydros at Pioneer/Burdekin and Borumba Dam by 2035

• A new Queensland supergrid connecting solar, wind, battery and hydrogen generators across the state

• Unlocking 22GW of new renewable capacity – eight times Queensland’s current level

• Publicly owned coal-fired power stations to convert to clean energy hubs to transition to, for example, hydrogen power, with job guarantees for workers

• Queensland’s publicly owned coal-fired power stations to stop reliance on burning coal by 2035

• 100,000 new jobs by 2040, most in regional Queensland

• 11.5GW of rooftop solar and 6GW of embedded batteries

• 95 per cent of investment in regional Queensland

• Building Queensland’s first hydrogen-ready gas turbine

The

a

Hydro, is expected to progress its PioneerBurdekin mega project, which could become the largest pumped hydro project in the world.

The project has the potential to deliver generation capacity up to 5GW for 24 hours, or 120GWh, thanks to the high quality wind and solar resources across North Queensland.

Queensland Hydro will conduct further studies and deliver a detailed assessment for the Pioneer-Burdekin project in 2024, including consultation with Traditional Owners and the community, hydrological modelling and assessment of environmental and social impacts, as well as commercial and financial modelling.

Innovative Water Solutions

WATER TECHNOLOGIES

Through its innovative solutions, Veolia Water Technologies enables industry, local authorities and citizens to optimize their use of resources for more efficient, environmentally-friendly and socially responsible outcomes.

We understand the importance of increasing the value of water and we do so by supplying high quality water, treating and reusing wastewater, producing and/or recovering energy, extracting raw materials and capitalizing on valuable byproducts.

www.veoliawatertechnologies.com.au

10 UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU NEWS

© Veolia Photo Library

plan details how

new publicly owned entity, Queensland

STATE APPROVES

50-YEAR WATER-SAVING

STRATEGY

The Victorian Government has approved Barwon Water’s Water for our Future (2022) 50-year urban water strategy, comprising 25 actions for better water management, including the sourcing of new water and the reuse and return of existing water.

The strategy was informed by the utility’s two-year-long Water for our Future community engagement program, which sourced more than 600 ideas from over 5,000 participating community members.

Barwon Water said the strategy seeks to manage water supplies in the face of a changing climate, while aiming to make the most of the challenges and opportunities presented by regional growth.

“Over the next 50 years, we will gradually transition to more climate-independent sources of supply, which aligns with actions set out in the Victorian Government’s recently announced Central and Gippsland Region Sustainable Water Strategy (SWS),” a Barwon Water spokesperson said.

Key highlights from the strategy include expanding the Melbourne-Geelong Pipeline (MGP) to service more customers and returning water to the Moorabool River.

GUIDED BORING SPECIALISTS

ABOUT US

Edge Underground is a precision microtunnelling contractor that operates in Australia and the USA. With a focus on innovative technology and expertise, Edge Underground designs and enhances the performance of trenchless equipment.

OUR SERVICES

UTILITY • NOVEMBER 2022

Microtunnelling

Pipe Jacking

Thrust Boring

Laser Tunnel Boring

Box Culvert Jacking

Canopy Tubes

•

•

•

•

•

•

* quotes@edgeunderground.co 8 www.edgeunderground.co ( JACKED 1300 522533

Winners announced FOR ENERGY NETWORK INDUSTRY AWARDS

The winners of the 2022 Energy Networks Australia (ENA) Industry Awards were announced at the ENA Annual Dinner.

The Awards’ three major categories recognised exceptional contributions to the network sector, leadership in the development of new innovations and outstanding initiatives in consumer engagement.

INDUSTRY CONTRIBUTION AWARD

The 2022 Industry Contribution Award was won by Laurie Curro from Horizon Power in Western Australia. Mr Curro was recognised for his contribution and commitment to the energy industry, in particular, power transmission and distribution in Western Australia.

Mr Curro made an outstanding contribution to the development

and operation of the Southwest Interconnected System (with Western Power) and regional networks (with Horizon Power), and was a member of ENA’s Asset Management Committee for many years.

INDUSTRY INNOVATION AWARD

The 2022 Industry Innovation Award winner was Endeavour Energy for its entry Using a Network Digital Twin for Digital Emergency Response and Resilience

Endeavour’s digital twin provides a virtual flood overlay across the

modelled 3D network. This innovation has been leveraged to improve public safety and restoration response times to several floods in the Hawkesbury region over 2021-2022.

CONSUMER ENGAGEMENT AWARD

The 2022 Consumer Engagement Award winners are AGN, AusNet Services and MGN, for their joint nomination Three Businesses, One Engagement Program for Victorians AGN, AusNet and MGN came together to design and deliver a single, integrated, statewide consumer and stakeholder engagement program, designed to inform and shape the submission of final plans to the AER on 1 July 2022, engaging with Victorians on gas services and prices.

Link-Seals offer hundreds of solutions to seal pipe penetrations ranging in size from 10mm to 3.6 metres diameter.

Link-Seals are suitable for most types of pipes including PVC, HDPE, Copper and Steel.

Resistant to water, oil, gas, aggressive chemicals and fire.

Projex Group helps calculate the right Link-Seal size and model for your application.

Link-Seal

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 12 NEWS

mail@projex.com.au 1800 001 114

Link-Seal Pipe Penetration Seal Solutions

Technology solutions for connected utilities.

Sensors & Edge Devices .

o Image o Temperature

o Level

Connectivity.

o Wired

o Wireless

o Mission Critical

o LTE/Mobile

Digital transformation is creating efficient, reliable and sustainable Australian utilities.

Platforms & Applications .

o On Premise

o Location + more Cybersecurity.

o IoT

o Secure technology for IEC 62443 standards

o In-cloud

o Visualisations

o Analytics

Connect and protect people, assets and the environment

With a 30-year legacy of providing resilient industrial technology solutions, our experience connecting and protecting people, assets and the environment, combined with our industry leading technology portfolio, means we’re the preferred partner for solving IIoT, industrial networking, cybersecurity, asset management and asset visibility challenges. Book a solutions workshop with our specialist team and see how digital transformation can benefit your business.

Sales Enquiries 1800 72 79 79 www.madison.tech

FIVE PUMPED HYDRO PROJECTS AWARDED $45 million total funding

Five pumped hydro projects in New South Wales have been awarded a total of $44.8 million in funding under the New South Wales Pumped Hydro Recoverable Grants Program, in a bid to advance the state’s pumped hydro future.

The five projects have a combined capacity of almost 1.75GW. They include:

• $11 million for Lake Lyell Pumped Hydro Energy Storage (EnergyAustralia)

• $9.64 million for Oven Mountain Pumped Hydro Energy Storage (OvenMountain)

• $5.31 million for Shoalhaven Hydro Expansion (Origin Energy)

• $9.44 million for Central West Pumped Hydro (ATCO Australia)

• $9.45 million for Muswellbrook Pumped Hydro (AGL Energy and Idemitsu Australia)

According to New South Wales Treasurer and Minister for Energy, Matt Kean, the program provides recoverable grants to pumped hydro developers to help cover upfront costs and lower investment barriers for the private sector.

“Funding agreements are already in place with five applicants who have received a total of $44.8 million to support pre-investment activities, establish project feasibility and develop a strategic business case,” Mr Kean said.

“If these pumped hydro projects proceed to construction, they are expected to create more than 2,300 jobs and attract $4.4 billion of private investment, which will help grow the economy and support the regions.

“New South Wales has the most ambitious renewable energy policy in the nation, which is needed to replace

ageing coal fired power stations and build a clean energy future for New South Wales.”

Mr Kean said pumped hydro is a key component of the state’s renewable energy plans and will provide clean, reliable power and create infrastructure jobs right across regional New South Wales.

“This is a win for New South Wales as these grants will be repaid to the government if a project reaches financial close, meaning that these same funds could be used to support even more projects in future,” Mr Kean said.

Pumped hydro works by using surplus renewable energy to pump water up a hill when it is sunny and windy, and releasing the water back down the hill through giant turbines that create electricity when it is still and dark.

By doing this, pumped hydro acts like a giant battery for the electricity system.

New South Wales has a target to build at least 2GW of new long duration storage by 2030, and the State Government has committed $97.5 million to accelerate pumped hydro projects that could meet that target. This includes funding for private projects, as well as funding to undertake site investigations for pumped hydro potential on existing WaterNSW dams.

Among the recipients is EnergyAustralia’s pumped hydro project at Lake Lyell near Lithgow.

EnergyAustralia Trading, Transition and Reputation Executive, Ross Edwards, said the Lake Lyell project would continue Lithgow’s proud history of power generation into the future and repurpose existing infrastructure to support the energy transition.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 14 NEWS

The Western Australian Government has invested $400,000 toward the construction of three community desalination units; built to test new desalination technologies for improved climate resilience and sustainability in community water supplies.

A brackish water desalination unit will be installed in Katanning during summer 2022-23, as part of a network of demonstration sites to examine how the technology can help overcome seasonal variability, reduce reliance on scheme water and support community development.

The Katanning unit will supply 30kL per day of fresh water to augment services for three local parks, as well as other town infrastructure.

This summer, a 100kL/day desalination unit will be installed at Merredin to service farm and town water needs, while a new 10kL/day salty groundwater system at Dumbleyung will service farm and town water supplies, as well as underpin repairs to the town’s swimming pool.

A further 30kL/day brackish water off grid reverse osmosis unit will be installed at the Wongutha Christian Aboriginal Parent-Directed School at Esperance, as part of a collaboration with the Federal Government’s National Water Grid Authority.

Western Australian Minister for Water, Dave Kelly, said long-term statistics indicated an urgent need for diversified water sources.

“The long-term statistics show that WA is experiencing reduced rainfall due to the impacts of climate change, with a record 12 Water Deficiency Declarations announced just two years ago in the Wheatbelt,” Mr Kelly said.

“This important work, supported by Water Corporation, will help to serve not only these first three communities but others in the future, as the technology is better understood and adopted throughout the state.”

The project received funding from the state’s WaterSmart Farms initiative, and is led by the Department of Primary Industries and Regional Development in partnership with Water Corporation.

Project stakeholders will also undertake case studies to examine the lifecycle costs and efficiency of these new systems.

The findings from the investigation will provide valuable information to assist regional communities and farmers to consider adopting the technology to build water resilience in a drying climate.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 15 NEWS

DESALINATION PILOT $400k for WA

NEW CEO WELCOMED AT AURORA ENERGY

Aurora Energy has welcomed its new CEO, Nigel Clark, who took the reins from outgoing CEO Rebecca Kardos in October 2022.

With more than two decades of experience in the energy sector, including multiple senior financial, strategic, and operational roles, Mr Clark is best known for his tenure at Momentum Energy, where he served as Managing Director for four years until Hydro Tasmania’s 2007 takeover.

Before joining Aurora Energy, Mr Clark was Chief Operations Officer at New Zealand’s Genesis Energy, and previously served as Director for Boards including the Snowy Hydro Corporation and Energy Retailers Association of Australia.

Aurora Energy Chairperson, Mary O’Kane, welcomed Mr Clark, signalling confidence in his extensive experience.

“With his extensive experience in the retail energy sector and his understanding of the Tasmanian market thanks to his time with Momentum, Nigel is the right person to lead the Aurora Energy team into the future,” Dr O’Kane said.

“Tasmanians expect their state-owned energy retailer to keep its costs to a minimum, while ensuring the products, services and support meet customer expectations. We have full confidence that Nigel will continue Rebecca Kardos’ outstanding work on both fronts.”

Mr Clark said he was excited for the opportunity to join Aurora.

“I am excited to be returning to the Australian energy market and serving the customers of Aurora and the broader Tasmanian community. I look forward to leading the business in its next phase of development in what continues to be a challenging, dynamic and evolving energy market,” he said.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 16 NEWS Visit us online for more info toolkwippumps.com.au P: +61 3 8805 0500 E: sales@toolkwippumps.com Available in: NSW • VIC • QLD • SA • TAS GET PUMPED! • Auto-prime Pumps • Electric & Hydraulic Submersible Pumps • Water Cart Trailers • Pontoons, Hoses & More... -DISTRIBUTORECO FRIENDLY PUMPING

Heads of Agreement secures FUTURE GAS SUPPLY FOR AUSTRALIA

The Australian Government has signed a new Heads of Agreement with East Coast LNG Exporters which is set to prevent a gas supply shortfall and secure competitively priced gas for the domestic market.

Australia’s east coast LNG exporters will ensure supply amid a forecast risk of energy system pressures next year as part of a package of measures – delivering secure, competitively-priced gas to domestic customers.

The new Heads of Agreement includes:

• LNG exporters to first offer uncontracted gas to the domestic market, on competitive terms, with reasonable notice, before exporting

• In respect of uncontracted gas, the principle that domestic gas customers will not pay more for the LNG exporters’ gas than international customers

• Commits LNG exporters to offering gas on terms consistent with a code of conduct

• Enhanced transparency and accountability, with quarterly compliance reporting to the Minister for Resources, with oversight by the competition regulator the ACCC

The negotiations ensure additional gas supply, improving security and affordability of domestic gas supplies in future years, while also introducing transparency measures to improve the information available to customers.

In July, the Australian Competition and Consumer Commission forecast a gas shortfall of 56 petajoules (PJ) for the domestic market in 2023.

The new commitments from LNG exporters will lead to an extra 157PJ for the domestic market in 2023, with the gas to be supplied in line with seasonal demand.

The new Heads of Agreement was signed by Federal Minister for Resources and Northern Australia, Madeleine King, and representatives from Australia Pacific LNG (APLNG), QGC Pty Ltd (operator of QCLNG), and Gladstone LNG (GLNG).

Minister King said the agreement will ensure Australians continue to have access to secure and reliable gas.

“The new supply commitments, and Heads of Agreement, will deliver gas to the domestic market when needed, and ensures future uncontracted gas will be offered to the domestic market first, on competitive and reasonable terms, before it is offered for export,” Ms King said.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 17 NEWS

tenders@lancogroup.com.au | www.lancogroup.com.au | 1300 1 LANCO (1300 152 626) Civil and Infrastructure Engineering | Project Management

GUARANTEEING MEASUREMENT ACCURACY

“What gets measured, gets improved” goes the saying imprecisely attributed to legendary management consultant Peter Drucker. Increasingly, though, good calibration requires more than whipping out the scales or a tape measure.

In a more and more exacting scientific world, extreme precision is required to deliver the best results to customers at a practical, industrial level.

Modern society is driven by data, which is created every time someone interacts with a connected device or software. When used wisely and properly, this data is enormously powerful but to be able to measure assets and functions with a high degree of reliability is key.

Over the last two and a half years, the COVID-19 pandemic has further highlighted the power and importance of accurate measurement. The well-documented logistics and supply chain problems mean that manufacturers need an advanced understanding of their inventory levels and – crucially – the availability of raw materials to keep the wheels of industry turning.

John Leadbetter, Managing Director of level and pressure-measuring equipment supplier, VEGA Australia, said customers are always looking at ways to improve, not only their own processes, but also to minimise downtime and delays.

“Remote access to information is becoming a very important issue with industry, and VEGA is at the forefront of this development,” Mr Leadbetter said.

An arm of the German-based giant VEGA Grieshaber AG, VEGA Australia has serviced the local market for almost four decades. Its customers include some of the biggest blue chip companies and span 12 key sectors including mining, oil and gas, food manufacturing and water management.

“It may be about measuring the pressure of slurry, air or water in a pipe, or the amount of material held within or above a mine or pipe or dam,” Mr Leadbetter said.

“The methods can be contact or non-contact, such as a radar transmitter, or a probe in a tank that picks up changes in conductivity or density.”

TRANSLATING DATA INTO MEASUREMENT

The underlying science aside, VEGA’s mission is to tackle customers’ practical day-to-day measurement challenges.

Mr Leadbetter said consumers tend to take information for granted, without any due thought to how this data translates to measurement.

“For example, 99.9 per cent of people turn their tap on in the morning and expect water to come out,” Mr Leadbetter said.

“But this happens because of accurate measurement, whether it’s the level of a dam, sewage flow rates or the reliability of tides and shipping.”

He said the internet-of-things revolution – the adoption of remote sensors – further highlights the imperatives of reliability and accuracy.

“Before they invest in logistics and resources, they need to know the information is going to be exactly what they are after,” Mr Leadbetter said.

Mr Leadbetter noted that the pace of technology advancements quickens each year – especially so in the case of process instrumentation. So with production processes becoming ever more complex, it’s crucial that the measurement technology used to control and monitor the processes is understandable and intuitive.

“VEGA has set itself the goal of developing innovative measurement technology that is easy to install and operate and offers maximum safety and reliability.”

For more information, please visit www.vega.com

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 18

NEWS | Sponsored editorial

IT DOESN’T JUST MEASURE VALUES. IT HAS VALUES. THE 6X ®. AVAILABLE NOW!

The VEGAPULS 6X: A radar level sensor that is not only technically perfect, it also takes the user into account. It’s easy to set up and at home in virtually any process or industrial environment. Made by a company that bases its decisions on values that are good for everybody.

VEGA. HOME OF VALUES.

www.vega.com/radar

ENHANCING ASSET MANAGEMENT WITH STATE-OF-THE-ART CONFLATION

The asset management capabilities of GIS rely on data integrated from a variety of sources. Discrepancies can often occur between different datasets, or between older and updated spatial data. For critical utility infrastructure applications, a simplistic fix to reconcile these differences will not pass muster. Achieving the most accurate dataset requires a strategic and rigorous approach to conflation by utilising advanced realignment techniques, excellent project management and extensive industry expertise.

As the GIS plays increasingly crucial roles in managing complex modern utility infrastructure networks, the need for quality and integrity of asset location data becomes ever more vital for efficient, cost-effective, and safe asset management. Accurate location data can also be key to unlocking the full capabilities of a digital twin and smart technologies to optimise performance.

However, as additional sources of data are integrated into a GIS and old data is updated, duplication and discrepancies between datasets can occur. Overlapping or adjacent sections of different maps may not match perfectly. Meanwhile, utilising newer, more precise location data frequently requires existing GIS data to be spatially adjusted to align with updated asset locations. To position assets accurately, preserve data integrity and merge overlapping datasets without conflicts, a composite combining the best elements of each map must be created. The process of combining and layering geographical information is known as conflation.

Digital cadastre modernisation is underway across much of Australia to better delineate land parcel boundaries. Superseding older map data with more precise location data enables boundaries to better align with GPS, high-resolution imagery, LiDAR, and other high-precision data collection methods. As utility assets are recorded in relation to land boundaries, any change to cadastre mapping requires a corresponding adjustment to infrastructure locations.

THE IMPORTANCE OF ACCURATE SPATIAL DATA

Successful conflation is essential to ensure a utility’s GIS uses the most precise, up-to-date location data for more effective asset management, outage management, field services management, project planning, performance analysis, emergency response and other uses. The quality and integrity of utility infrastructure location data is critical for an array of reasons, and its importance continues to increase as old assets reach end of life and require replacement, and networks are expanded and upgraded, resulting in smarter and more complex networks required to meet changing consumer needs.

Damage to underground utility infrastructure due to inaccurate positional data is an ongoing concern for the industry. Utility strikes result in significant financial costs and service interruptions and pose serious and potentially life-threatening safety hazards to workers and members of the public.

Higher-precision location data vastly expands the potential applications of GIS in the utility sector. As digital transformation gains momentum, the ability to accurately

visualise infrastructure locations underpins a growing range of smart technologies to make utilities’ networks, operations and services safer and more efficient, and to unlock additional capabilities and value streams.

Some of the additional benefits of higher-precision location data include:

• The ability to integrate with aerial imagery and newgeneration mapping systems

• Reduced costs associated with checking and accessing locations when maintaining, upgrading or replacing network assets

• Improved billing accuracy

• More accurate reporting leading to improved regulatory compliance

SUCCESSFUL CONFLATION FOR HIGHERPRECISION MAPPING

To achieve a suitable level of data accuracy in the GIS, conflation must be undertaken using mathematically rigorous best-practice methods and optimised workflows. A simplistic ‘rubber-sheeting’ solution, shifting all vertices from one dataset to another, will not suffice.

A successful conflation project calls for expertise and a strategic, scalable approach using advanced and robust mathematical models to realign and reconcile conflicting datasets, supported by a high-performance adjustment engine. The conflation procedures need to allow for the application of business rules and constraints to preserve network topology and connectivity, as well as maintain straight lines, angles, and other important attributes. Quality assurance processes should ensure outliers are excluded and any other issues that could reduce accuracy are rectified before the updated dataset is applied to a GIS. Data security and the ability to rollback changes are essential. Most importantly, a utility’s business must not be interrupted, allowing work to continue while conflation is underway.

EXPERT CONFLATION FOR UTILITY ASSETS

we-do-IT has extensive experience delivering utility industry conflation projects on time and on budget. Utilising proprietary quality-assurance and project-management processes, robust technology and advanced mathematical modelling, we-do-IT helps utilities achieve the highest levels of GIS location accuracy, all without interrupting business as usual.

To find out more contact we-do-IT on (03) 9098 8617 or email info@we-do-it.com to speak with a conflation expert.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 20 NEWS | Sponsored editorial

WE DO SPATIAL I.T. SOLUTIONS. WE DO CONFLATION SOLUTIONS.

CELEBRATING OVER 25 YEARS IN THE GIS SECTOR

we-do-IT are a leading technology partner in spatial systems and data enablement. We help utilities harness the power of location intelligence.

MELBOURNE • BRISBANE • AUCKLAND • DENVER • LONDON • HAMBURG • HYDERABAD • SINGAPORE CONTACT US NOW TO DISCUSS YOUR NEXT GIS PROJECT. +61 3 9098 8617 INFO@WE-DO-IT.COM WE DO GIS CONSULTING. WE DO GIS DATA ENGINEERING.

FUTURE TECHNOLOGY OPPORTUNITIES FOR UTILITIES

During a recent series of technology road shows, Madison Technologies has talked at length with customers in the power and water utilities sectors, learning about the industrial technology challenges and opportunities they are currently facing.

Anumber of topics and technologies have formed the basis of these conversations, including edge computing, connectivity, IIoT technologies, and the one word that is front of mind for everyone –cybersecurity.

CUSTOMERS ARE TALKING ABOUT CYBERSECURITY

Cybersecurity is an increasingly important conversation amongst Madison Technologies customers, especially as the industry sees the continued convergence of IT and OT infrastructures. The merging of these two systems is creating more surface for attackers to enter through, and in several recent high-profile attacks, perpetrators gained access through vulnerabilities created by IT/OT convergence.

Confidentiality, Integrity and Availability, also known as the CIA triad, is a model designed to guide cybersecurity policies and practices, but Madison Tech is also talking to its customers about Visibility

Visibility, including visibility of what is connected to your network, the traffic on your network, how networks are segmented, what needs to be patched, and what needs to be modernised, is an important element of a company’s cybersecurity practices.

Madison Tech is demonstrating to customers that intrusion prevention can be achieved with smart networking technologies, helping secure network infrastructure with visibility capabilities. This makes it easy for users to identify all devices on the network and their communication patterns, and helps ensure the continuity, resilience, and safety of industrial operations.

CUSTOMERS ARE TALKING ABOUT INCREASING EFFICIENCIES

In the face of rising demand, customers want to know how digitisation can help them increase operational efficiency. With the advancement of edge computing, machine learning and AI, it is now possible to analyse multivariate data to predict and avoid operational failures and downtime, as decisions can be derived where the asset operation is occurring.

By building a model using data collected during normal operations, a process beginning to drift or change can be identified, predicting a failure before it occurs. This prediction allows preventative maintenance to be undertaken, and a complete shutdown or unplanned downtime can be avoided. Moving from reactive to proactive to predictive maintenance can enable utility providers across

Australia to increase their overall operational performance.

CUSTOMERS ARE TALKING ABOUT DIGITISING DATA MEASUREMENT

Dispersed and remote assets have a unique set of logistical challenges. The measuring and reading of meters is, in many cases, still a manual process. Conversations to improve the efficiency and accuracy of this process continue to revolve around implementing Industrial Internet of Things (IIoT) devices. Digitising this data capture process with a data logger, such as Captis IIoT data loggers, allows this data reading to be collected automatically, efficiently, and accurately.

Another example of a specific challenge water utilities are facing is service interruptions from blockages. IIoT devices containing sensors are enabling wastewater utilities to monitor sewage systems and avoid overflows by alerting them to blockages before they become problems.

Madison Technologies has recently provided a solution for a large Australian water authority and the proactive nature of this digitised data capture is reducing service interruptions, as well as reducing the risk to the public and the environment from spillages.

To learn more about these topics, or to book a solutions workshop with Madison Technologies’ technical team, visit www.madison.tech or phone 1800 72 79 79

22 NEWS | Sponsored editorial

UNITYWATER CEO Anna Jack son on creating a SUSTAINABLE UTILITY

by Jessica Dickers, Managing Editor, Utility Magazine

In July this year, Anna Jackson joined South East Queensland water utility Unitywater as its new CEO. Previously SA Water’s General Manager Strategy, Engagement and Innovation, Ms Jackson is keenly aware of the challenges facing water utilities and recent developments in customer engagement. She sat down with Utility Magazine Editor, Jessica Dickers, to discuss the impacts of climate change and population growth, the uptake of digital meters, and the vision for her new role –all of which tie in with an overarching theme of a sustainable water future.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 24 INDUSTRY INSIGHTS

While most water utilities around Australia are facing similar challenges, Unitywater’s location means it’s been hit with extreme weather events as well as predicted rapid population growth, which Ms Jackson said are the most pressing issues she’s encountering in her new position.

Unitywater supplies water and sewage treatment services to Moreton Bay, Sunshine Coast and Noosa in SouthEast Queensland.

“It’s those two issues in combination with each other,” Ms Jackson said. “If you take into account our entire service area from just north of Brisbane through to Noosa, there's about 800,000 people and that's expected to grow to more like a million in the lead up to the 2032 Brisbane Olympics.

“There's a lot of consideration for what that means for both our infrastructure and our services. For instance as a progressive utility, I’m seeking out value-adding elements such as liveability and improved waterway health which we can build in as outcomes along the way to delivering on our net zero, sustainable infrastructure, climate readiness and reconciliation goals.”

Before joining SA Water in 2017 as one of six General Managers, Ms Jackson worked at large multinational Coffey in international development, and aerospace and defence technology company Raytheon. At SA Water she was responsible for business strategy, water security and quality, innovation, customer engagement and environmental and social governance, and spent time as the General Manager of Customer and Commercial. This experience has helped shape some clear priorities for her leadership at Unitywater.

“For me, part of any future-proofing of our infrastructure and services is to increase our reuse from our sewage treatment plants so over time they become water and resource recovery centres.”

Ms Jackson said other priorities include increasing

Unitywater’s non-regulated business activities and continuing to foster an engaged culture at the utility.

“We need to balance our investment required for these initiatives with customer prices, so we are looking at broader business investments and activities.

“Then a really important priority is to work with the Unitywater team – 700 people – plus our contractors, to build on a culture of proactive delivery and ideas generation.”

WORKING TOWARDS NET ZERO

Ms Jackson said that, like many other Australian utilities, Unitywater has goals to meet net zero emissions targets by 2050, with the utility's operations and management geared towards mitigating the impacts of climate change and creating more sustainable services. Water utilities are at the forefront of these impacts with water scarcity and quality becoming major issues.

“We are going to achieve net zero carbon, nitrogen and phosphorus. We are heading for that 2050 target and that's going to involve considerable collaboration across the region, not just with other water industry participants, partner councils, traditional owners, state and federal government.

“For me, reuse is incredibly important. We have a lot of sewage treatment plants and I will consider how we push them for reuse as much as possible. We have the Wamuran Irrigation Scheme under construction at the moment, which is a great example of reliable and high quality recycled water for irrigation for turf and berry growers”

Ms Jackson is a member of the Australian Water Partnership Advisory Committee as well as Water Services Association of Australia’s Liveable Communities Committee. She believes that when it comes to creating liveable sustainable communities, the water utilities are uniquely positioned to learn from each other. For example, looking at the innovations Victorian water utilities have already started, with state-based targets of 2035.

“We are open to learning from their experiences and see it as a starting

point for us to consider those initiatives in our context.”

THE BLUE HEART AND CUSTOMER ENGAGEMENT

Besides increased water and by-product reuse, how else can we see sustainable operations in action at Unitywater? Ms Jackson said one particularly exciting project is the Blue Heart – a partnership with Sunshine Coast Council and the Queensland Department of Environment and Science which covers around 5,000 hectares and includes Unitywater’s Yandina Creek Wetland.

“The project area is in the Maroochy River floodplain,” Ms Jackson said. “So it's both a blue carbon sink and floodplain management, which is fantastic from an environmental management and climate change point of view.

“Our wetland is a nutrient offset project. It is removing nutrients and sediments from Maroochy River, improving water quality and overall river health. We'll be working with our partners on amenities like recreational walks, viewing locations, and making it more of an attraction. It just ticks a lot of boxes in terms of environmental management and community amenity.”

The other project underway at Unitywater that Ms Jackson is taking a keen interest in is called Water Matters, which aims to increase customer engagement, an area that she has a lot

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 25 INDUSTRY INSIGHTS

of experience with due to her previous role at SA Water.

Working with Sunshine Coast Council, Noosa Council, and Seqwater, the project takes into account the integrated water cycle with customers' views of what they would like and how they would want to see things moving forward.

“We're right on the cusp of doing more of that customer engagement work, which is just going to be so interesting to hear firsthand from our customers what their priorities are when it comes to sustainable water use and making sure we are making

the most of that integrated water management cycle,” Ms Jackson said.

THE NEXT GENERATION OF WATER PROFESSIONALS

While it’s critical for executives and senior leaders to have sustainability front and centre in their work every day, Ms Jackson said it’s also important for people coming into the water sector to have similar views and priorities, regardless of their roles.

“We need people in the industry who are prepared to put a climate and sustainability lens across projects and initiatives. It’s almost routine now

that if you're looking at something in the sector, you're also thinking, ‘how would this work in terms of an extreme weather event? How would this work in terms of drought? How would this work if sea levels are rising? How would this work in terms of remnant vegetation and habitats? How would it work in terms of nutrients and cleaner waterways? And most importantly, what are some ideas that I can bring to the table to solve these issues, how can I tackle this with research, development and collaboration?

“My view is that wherever you work in the industry, whichever role you

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 26

INDUSTRY INSIGHTS

have and whatever your background is, bringing that mindset is really important,” Ms Jackson said.

She also said that the industry needs people who are curious and willing to learn and try new things, with one way to achieve this being accepting short rotations into other areas of the organisation to round out their skills and build a holistic view of how everything works.

DIGITISING AUSTRALIAN WATER UTILITIES

Every day Unitywater operates and maintains more than $3.4 billion of infrastructure. Most utilities have already realised the significant impact new technologies can have on operations and are at some stage of digital transformation. For Ms Jackson, there is one particular technology that she believes is really the future of the sector.

“The technologies for me that have the potential to have a significant and positive impact for customers are still being rolled out, which are digital meters and sensors; acoustic sensors, and other sensors in our distribution networks, whether it's sewer or water.

“They are really powerful tools in terms of benefits realisation from both an operations and maintenance, and from a customer perspective.”

Ms Jackson said Unitywater has sensors throughout its distribution networks, and has rolled out a trial of smart meters at the customer end as well. Sensors give utilities a heads up on potential issues before they become costly and damaging.

“We are starting to see as an industry it becoming the norm to roll out sensors through our networks, especially on roads where we know it would have a really significant impact if you had a main break. If you can be ahead of that disruption and avoid all of those things that come with a large main break in the future, that would be excellent, and you could operate your networks in a consistently proactive and intelligent way.”

LESSONS FOR OTHER UTILITIES AND EXECUTIVES

As Ms Jackson moves forward and executes her vision for Unitywater as its new CEO, she plans to utilise what she describes as a “very collaborative

sector” and recommends this for other utilities.

“One of the biggest lessons I’ve learnt is don't try and do everything on your own. Partnerships are key and you can do so much more if you partner with the right organisations, and it's incredibly rewarding as well.

“The second thing is respecting your stakeholders and your customers and listening to them if they say to you, ‘this is what we think and this is what we want’. This is our priority. I think the most important thing you can do is make it clear that you have heard and you believe them, and you're going to act on that.

“In terms of collaboration, I'm learning from other chief executives and managing directors in the water industry all the time, and they are a generous and helpful group. I'm pleased to be able to phone them and ask for their experience in dealing with different issues, and that's one of the real benefits of being part of this industry. I think that that's one of the real benefits of being in this industry, that you could even do that, it's wonderful.”

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 27 INDUSTRY INSIGHTS

Making waves:TRANSFORMING THE WATER INDUSTRY

While climate change is putting immense pressure on the global supply of water, digitalisation can improve sustainability – it’s one of the top three benefits of digital transformation. Here, Gentrack selected a panel of global experts to share their views on industry challenges and explore the key to digitising.

Water is a natural resource many of us take for granted, but recently it has been the subject of global concern. While devastating floods are wreaking havoc across Australia, the Northern Hemisphere is battling record breaking water shortages, including the worst European drought for 500 years.

Outside of our industry, we seldom appreciate the millennia of engineering advancements that have led to a system of safe, clean drinking water delivered directly into our homes and the removal of unwanted waste – or the immense pressure that system is under today.

Aside from the overwhelming effects of climate change, the global water industry is battling urbanisation and population growth, regulatory and political pressure, all while contending with aging infrastructure. And it’s not just the physical assets that are aging – 75 per cent of global utility customers are managed on legacy IT systems1. As a transformation powerhouse, we wanted to get to the bottom of this digital delay in the water sector.

While sustainability is a significant positive outcome of digitalisation, it was customer experience that stood out as the top benefit. This is unsurprising considering that many water firms don’t utilise data to inform intelligent customer solutions and propositions.

GIVEN THAT THE BENEFITS OF DIGITAL TRANSFORMATION ARE CLEAR, WHY ARE MANY WATER FIRMS RELYING ON MANUAL PROCESSES?

Our panel (83 per cent) claimed that during a transformation, operational and culture change present the biggest challenges, but poor change management capabilities are the biggest blocker to starting a transformation.

This is despite reports from Global Water Intelligence that global digitisation of the sector could lead to savings of approximately USD$176 billion on total expenditure over five years for drinking water treatment, distribution, customer services, metering and billing.

HOW DO WE GET PAST THESE CHALLENGES?

If culture is one of the key blockers, then the simple reality is this – it’s time to change the culture and introduce innovative thinkers into the business. Some of our panel even noted that going digital drives recruitment of leading tech talent.

What’s more, our panel agreed that engaging a proven technology partner is key to overcoming poor change management. When 70 per cent of transformation projects fail, it’s understandable that the water sector is resistant to change. But being a digital laggard isn’t the answer. The global challenges facing the water sector will become unmanageable for those relying on manual processes.

Working with a delivery partner with a ten per cent transformation success rate, water businesses can mitigate the migration risks and focus on the benefits of delivering world-class customer and operational excellence, slashing their cost to serve and driving continuous innovation.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 28 INDUSTRY INSIGHTS | Sponsored editorial

1 Based on data from Gartner “Market Guide for Utility Customer Systems” Published 10 November 2021

For more information, please visit www.gentrack.com

Made with experience

As one of Australia’s largest broadband networks, our dedicated and experienced nbn® New Developments team has delivered nbn network access to more than 1.2 million new development premises nationwide.

We can do more for your build

Make nbn part of the plan

Visit nbn.com.au/newdevelopments

GENUINE WATER COLLABORATION through Reconciliation Action Plans

Barwon Water’s award-winning Aboriginal Employment and Retention Strategy is just one part of its approach to working with Traditional Owners.

Barwon Water’s nationally-recognised Aboriginal Employment and Retention Strategy highlights the work the water corporation is doing to continue improving the cultural safety of its workplace as it seeks to increase the employment of First Nations people in all levels of the organisation.

Barwon Water Managing Director, Tracey Slatter, said that from board level down, the water corporation had tried to drive a whole-of-organisation approach to boosting Traditional Owner involvement in water management.

“At every board meeting, as well as an Acknowledgement of Country, we have a monthly reflection on First Nations achievements and issues for the month,” Ms Slatter said.

Ms Slatter said that by doing so, Barwon Water was striving to become a culturally safe and inclusive place for First Nations people to participate as employees, and thrive, grow and influence the organisation.

“Our Aboriginal Employment and Retention Strategy, which won the state and national Australian Water Association Award for Organisational Excellence, is a good example of how we are trying to achieve what we want in this space,” she said.

Creating the strategy was a strong commitment in Barwon Water’s Innovate Reconciliation Action Plan (RAP).

At the heart of the strategy is understanding and embedding First Nations cultural values and the holistic wellbeing of First Nations Peoples.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 30

INDUSTRY INSIGHTS

BARWON WATER DEPUTY CHAIR ELAINE CARBINES, MEMBER FOR GEELONG AND PARLIAMENTARY SECRETARY FOR FIRST PEOPLES CHRISTINE COUZENS, TOOGEE WOMAN AND BARWON ASSET SOLUTIONS’ EMPLOYEE HAYLEY JONES, AND BARWON WATER MANAGING DIRECTOR TRACEY SLATTER WITH THE STATE AND NATIONAL AWA AWARDS WON BY BARWON WATER’S ABORIGINAL EMPLOYMENT AND RETENTION STRATEGY.

It provides the foundations for creating and delivering culturally appropriate, respectful and meaningful outcomes for First Nations employees.

The strategy holds Barwon Water accountable for developing meaningful connections and employment opportunities with First Nations peoples in its service region, to enable their knowledge, understanding and water values to form an integral part of the organisation’s water management and planning programs.

UNDERSTANDING AND SUPPORTING CULTURES AND HISTORIES

Two successful initiatives coming from the strategy include the twelve-month traineeship program, developed in partnership with Wan-Yaari Aboriginal Consultancy Services and Gforce Employment Solutions, as well as an in-depth Connection to Country program for all employees, which includes cultural heritage education and visits to culturally significant sites in the region.

“Partnering with Wan-Yaari Aboriginal Consultancy Services, we put a lot of work into the strategy and our Innovate RAP,” Ms Slatter said.

“It’s also been part of our journey in furthering our understanding and importance of First Nations Cultural Values while creating a culturally safe work environment as we strive to attract increasing numbers of First Nations employees into career pathways that are diverse and inclusive.”

Ms Slatter said in addition to the strategy, building strong relationships with Traditional Owner groups was crucial to Barwon Water’s work.

“We would like to give a special thanks to Wadawurrung and Eastern Maar Traditional Owners for helping guide us to see the land, water and environment around us through the eyes of a Traditional Owner.

“Their willingness to share knowledge and stories assists us to understand and support their cultures and histories, in turn helping us to Connect with Country.”

Ms Slatter said there had been some milestone moments in Barwon Water’s reconciliation journey since the Innovate RAP was implemented in 2018.

These included the decision to transfer land near Ballan Reservoir to the Wadawurrung, the partnership with the Wadawurrung on the Porronggitj Karrong project on the land around the Aqueduct in Geelong, and Caring for Country tours with Traditional Owners across Barwon Water’s service area, where staff and Traditional Owners shared stories and knowledge.

Ms Slatter said many staff had commented on how much they valued the experiences, which has changed their understanding and mindset.

“Every time we have the benefit of learning more, we realise how much better our organisation and region will be when we – in true reconciliation – create a new future that melds our knowledge for common purpose.”

Ms Slatter said she and other Barwon Water staff had spent valuable time with Traditional Owners learning from

them about how to think differently about the lands and water that the water corporation manages.

“I am very grateful for the generosity Traditional Owners have shown in sharing their deep knowledge.”

OPENING BARWON WATER LAND

Ms Slatter said that while Barwon Water had made huge strides in its reconciliation journey, she was looking forward to the organisation going further and embedding reconciliation in everything it did as part of its Stretch RAP, which was now with Reconciliation Australia for review.

“The Stretch RAP outlines the steps we will take to ensure that Reconciliation becomes part of everything we do at Barwon Water. It shows we will continue to invest in relationships with Traditional Owner and First Nations organisations and advance reconciliation within our organisation and our sphere of influence in the region and the broader water industry.”

Ms Slatter said that locally, the Barwon River was increasingly becoming a focal point for First Nations participation in water, including through the Porronggitj Karrong project, where Barwon Water is partnering with Wadawurrung Traditional Owners to explore opportunities to open Barwon Water land, which is no longer required for operational purposes, to the community.

The 66-hectare parcel of land, which features a heritagelisted aqueduct, is significant for the Wadawurrung Traditional Owners who have a connection with the river and surrounds dating back thousands of years.

“In partnership with Wadawurrung and other stakeholders, we are engaging broadly to develop a plan that, when implemented, will enable the area to be accessed and enjoyed by the whole community for its high ecological, heritage, cultural and recreational values,” Ms Slatter said.

Referred to as the Porronggitj Karrong (Place of the Brolga) project, the cultural and community precinct proposed for the area is intended to be a place people can visit to walk, paddle, and reflect.

It will also be a place where traditional land and water management practices are trialled to rehabilitate and to learn about the local environment. Plans are being developed in partnership with Wadawurrung Traditional Owners and in consultation with the broader Geelong community.

“The Wadawurrung are having significant input into this project and we’re learning a lot as we go,” Ms Slatter said.

Meanwhile, Barwon Water also has a three-year partnership agreement in place with Wadawurrung Traditional Owners Aboriginal Corporation, which Ms Slatter said had been an important step in ensuring genuine collaboration with Traditional Owners on various projects.

“The actions and projects we have implemented are contributing to positive change both within our business, as well as the broader community.

“We look forward to continuing to work in partnership with the traditional owners of the land on which we work.

“We know there is a lot of work still to be done in this area, but we think we are on the right path,” Ms Slatter said.

UTILITY • NOVEMBER 2022 WWW.UTILITYMAGAZINE.COM.AU 31

INDUSTRY INSIGHTS

INDUSTRY LEADING TECH

UNLOCKING CLEAN ENERGY POTENTIAL

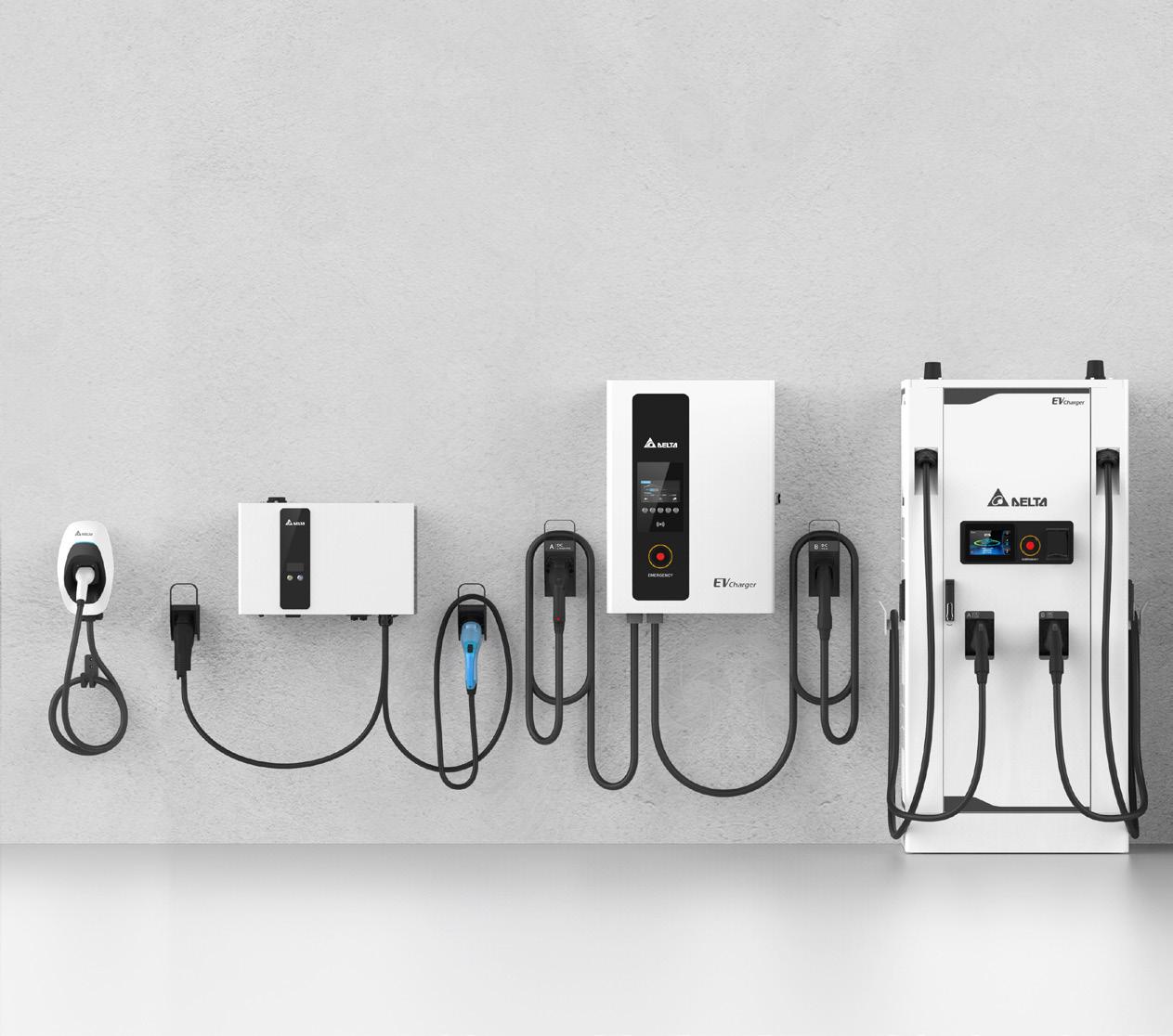

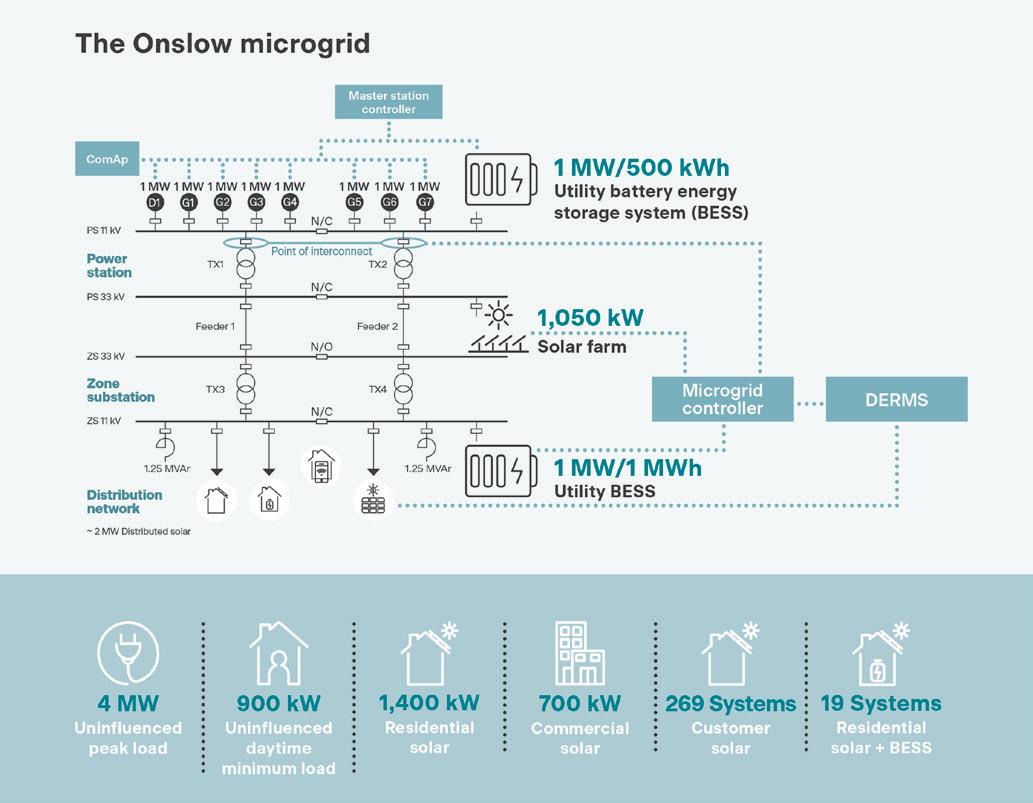

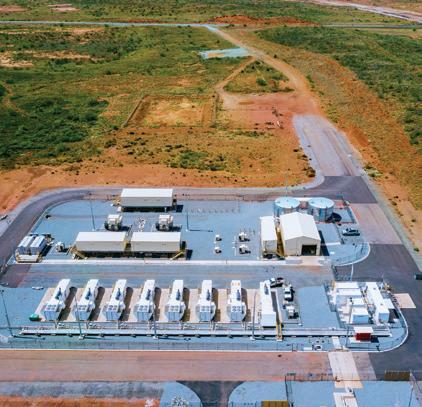

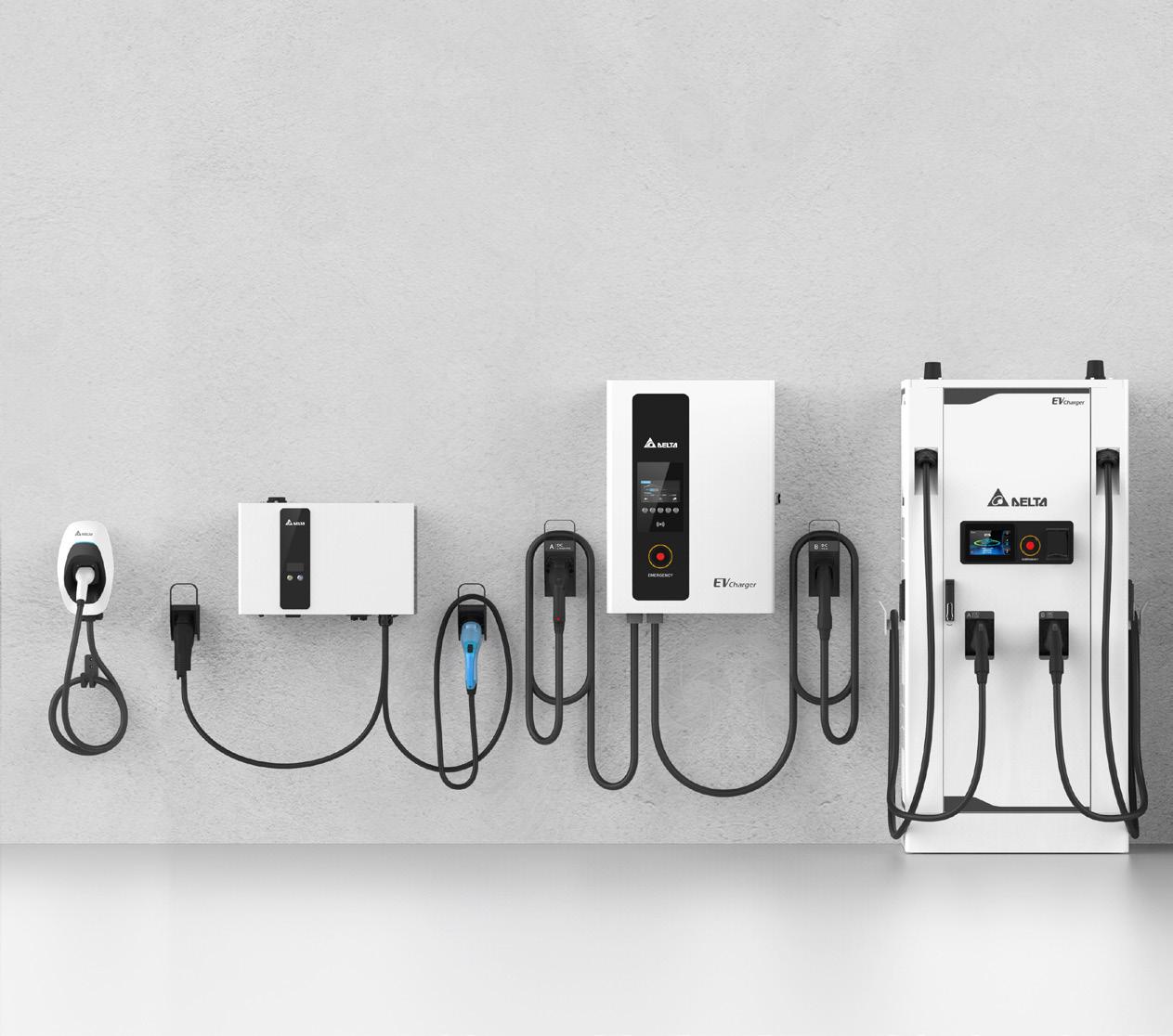

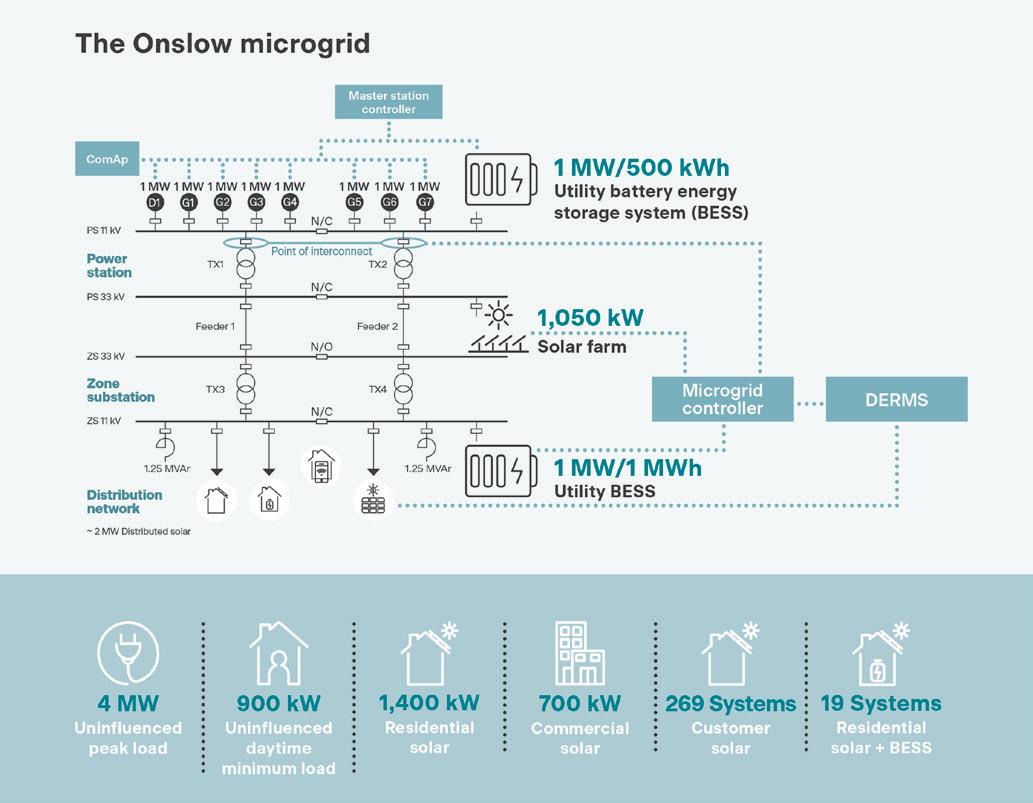

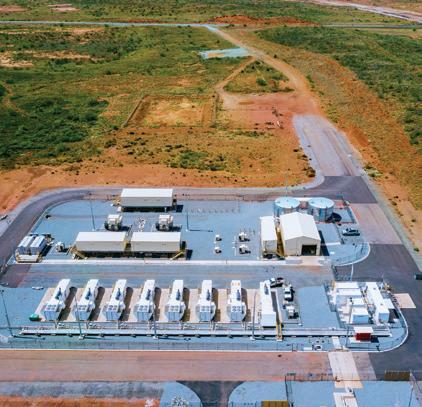

People living in regional and remote Western Australia will soon be able to embrace clean energy technologies and reduce their energy bills, with Horizon Power rolling out industry leading technology to create smart, integrated, and cleaner energy systems across the state from early 2023.

The state government owned power provider is deploying a technology system that enables safe, stable, and large-scale integration of customer and utility energy resources, making it easier to connect to solar and energy storage and providing a pathway to decarbonised energy systems.

The energy management technology, called a Distributed Energy Resources Management System or DERMS, enables utility owned energy resources, such as power stations, solar farms, and batteries, to be safely integrated with distributed customer owned energy resources,

such as rooftop solar, batteries, and electric vehicles.

The DERMS can monitor generation from both customers and the utility in real-time and use predictive analytics, including weather pattern analysis, to forecast changes in generation and demand and make constant adjustments so the energy system remains stable.

Horizon Power General Manager

Technology & Digital Transformation, Ray Achemedei, likens the technology to the conductor of an orchestra, because the system coordinates generation from the different power sources of gas, large-scale solar and rooftop solar.

“DERMS is the conductor and the orchestrator of the flow of energy throughout the network, both utility and customer energy generation sources,” Mr Achemedei said.

“With approximately 60 per cent of Horizon Power’s energy systems currently dealing with limits on rooftop solar, deploying a distributed energy resources management system will increase solar access for our customers, lower their energy bills, and help reduce emissions.